Definition: Steam trap efficiency is a measure of how well a steam trap performs its intended function of removing condensate while minimizing steam loss.

Click the Translate button(see right) on this post to set your Own Language to understand more perfectly!!

Steam Trap Efficiency Calculator

Definition Continue: How to Trap Steam

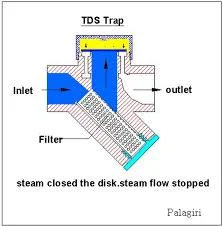

A steam trap is a device used in steam systems to automatically remove condensate (water formed from condensed steam) while preventing the escape of steam. This is crucial for maintaining system efficiency and preventing damage.

Key Components of a Steam Trap:

Inlet: Where steam and condensate enter the trap.

Outlet: Where condensate exits the trap.

Valve: Controls the flow of condensate and steam.

Sensing Element: Detects the difference between steam and condensate.

Types of Steam Traps:

Thermodynamic Traps: Utilize the difference in physical properties between steam and condensate (e.g., velocity, pressure).

Thermostatic Traps: Rely on the temperature difference between steam and condensate.

Mechanical Traps: Use a float or bucket mechanism to differentiate between steam and condensate.

Steam Trap Efficiency

Steam trap efficiency is a measure of how well a steam trap performs its intended function of removing condensate while minimizing steam loss.

Steam TrapCapacity (lb/hr): The maximum amount of condensate a steam trap can handle per hour without causing backup or flooding.

Steam Trap Loss (lb/hr): The amount of steam unintentionally discharged by the steam trap.

A higher steam trap capacity and lower steam trap loss indicate a more efficient steam trap.

Factors Affecting Steam Trap Efficiency:

Correct Trap Selection: Choosing the right type of steam trap for the specific application.

Proper Installation: Ensuring correct orientation and piping.

Regular Maintenance: Periodic inspection and cleaning to prevent malfunctions.

Load Variations: Fluctuations in steam demand can impact efficiency.

Note: To calculate steam trap efficiency, you would typically compare the actual condensate handled to the theoretical capacity and the actual steam loss to the total steam used.I believe there might be a misunderstanding. The previous response about liquid names, flash points, and flammability is not directly related to steam traps. If you have any other questions about steam traps or their applications, feel free to ask.

Would you like to delve deeper into a specific aspect of steam traps, such as sizing, selection, or troubleshooting?

Let's Dive Deeper into Steam Traps

Steam Trap Sizing

Steam trap sizing is critical to ensure optimal performance and prevent issues like water hammer, steam loss, and condensate backup.

Key factors influencing steam trap size:

Condensate load: The amount of condensate to be removed.

Steam pressure: The operating pressure of the steam system.

Steam temperature: The temperature of the steam.

Trap type: Different trap types have varying capacities.

Installation location: The position of the trap in the steam system.

Sizing methods:

Manufacturer's guidelines: Most steam trap manufacturers provide sizing charts and calculators based on their product range.

Calculation-based methods: Involve using formulas to determine the required trap capacity based on factors like condensate load and steam conditions.

Example:

To size a steam trap for a heat exchanger, you would calculate the expected condensate load based on the heat transfer rate and steam conditions. Then, you would use the manufacturer's sizing chart or a calculation method to determine the appropriate trap size.

Steam Trap Selection

Steam trap selection involves choosing the right type of trap for a specific application based on factors like:

Condensate characteristics: Temperature, purity, and volume.

Steam conditions: Pressure, temperature, and quality.

Installation location: Accessibility, orientation, and piping configuration.

Operating environment: Temperature, pressure, and corrosive conditions.

Common types of steam traps:

Thermodynamic traps: Suitable for general-purpose applications.

Thermostatic traps: Used for applications with fluctuating loads.

Mechanical traps: Best for handling large amounts of condensate or dirty conditions.

Example:

For a steam-heated tank with intermittent steam demand, a thermostatic trap might be suitable due to its ability to handle load variations.

Steam Trap Troubleshooting

Steam trap troubleshooting involves identifying and resolving issues that prevent optimal performance.

Common problems:

Trap failure: Malfunction of the trap's internal components.

Clogging: Blockage of the trap's orifice by dirt or scale.

Erosion: Wear of internal components due to high-velocity condensate.

Steam leakage: Loss of steam due to a faulty valve or sensing element.

Troubleshooting methods:

Visual inspection: Checking for signs of leakage, damage, or foreign objects.

Temperature measurement: Comparing inlet and outlet temperatures to determine trap status.

Acoustic inspection: Listening for abnormal sounds indicating problems.

Ultrasonic inspection: Detecting steam leaks using ultrasonic technology.

Example:

If a steam trap is suspected of leaking steam, an ultrasonic inspection can be used to pinpoint the leak source.

How is it possible to earn money using the knowledge of Steam Trap Calculation in real-life applications??????

Earning Money with Steam Trap Knowledge

Understanding steam trap calculations and applications can lead to significant cost savings and efficiency improvements in various industries. Here's how this knowledge can be monetized:

1. Energy Management and Consulting:

Energy Audits: Identify inefficiencies in steam systems through steam trap assessments.

Cost-Saving Recommendations: Propose solutions to reduce energy consumption and operating costs.

Implementation Support: Assist in the installation and maintenance of optimized steam trap systems.

2. Steam System Design and Optimization:

Design and Installation: Create efficient steam systems by selecting and sizing appropriate steam traps.

System Upgrades: Improve existing systems through steam trap modifications or replacements.

Performance Analysis: Evaluate steam system performance and identify areas for improvement.

3. Maintenance and Repair Services:

Steam Trap Inspection and Maintenance: Offer regular inspection and maintenance services to prevent failures.

Troubleshooting and Repair: Diagnose and fix steam trap issues to restore system efficiency.

Replacement Services: Provide replacement steam traps when necessary.

4. Training and Education:

Workshops and Seminars: Conduct training programs on steam trap selection, installation, and maintenance.

Online Courses: Develop online training modules for a wider audience.

Technical Publications: Write articles or books on steam trap technology.

5. Product Development and Sales:

Steam Trap Design: Develop innovative steam trap designs to improve efficiency and reliability.

Product Sales: Sell steam traps and related products to industrial customers.

After-Sales Support: Provide technical support and maintenance services for sold products.

6. Research and Development:

New Steam Trap Technologies: Develop advanced steam trap designs and materials.

Performance Testing: Conduct research to improve steam trap efficiency and reliability.

By combining technical expertise with a strong understanding of industrial needs, professionals can build successful careers in the steam system optimization field.

Would you like to focus on a specific area or industry where steam trap knowledge can be applied?

Do YOU Want To Earn Money In Various Ways, Click The Link & Explore Your Field of Interest!!!

No comments:

Post a Comment