Definition:The Liquid-Liquid Extraction McCabe-Thiele method doesn't have a single defining equation. It's a graphical technique used to determine the minimum number of theoretical stages (equilibrium contacts) required in a countercurrent extraction process.

Click the Translate button(see right) on this post to set your Own Language to understand more perfectly!!

Liquid-Liquid Extraction McCabe-Thiele Calculator

Continue Definition:

The Liquid-Liquid Extraction McCabe-Thiele method doesn't have a single defining equation. It's a graphical technique used to determine the minimum number of theoretical stages (equilibrium contacts) required in a countercurrent extraction process.

Here's a breakdown of the relevant factors and how they are used with the McCabe-Thiele method:

Factors:

Feed Flow Rate (L/h): This represents the volumetric flow rate of the feed solution entering the extraction process. (e.g., 100 L/h)

Feed Concentration (%): This indicates the initial concentration of the solute in the feed solution. (e.g., 1 wt% solute)

Solvent Ratio (mL/mL): This is the ratio of the volumetric flow rate of the solvent to the volumetric flow rate of the feed. (e.g., 2 mL solvent / 1 mL feed)

Extract Concentration (%): This represents the desired concentration of the solute in the extract leaving the process. (e.g., 5 wt% solute)>

Relative Efficiency (%): This is an empirical factor (often estimated between 50-80%) that accounts for deviations from ideal equilibrium due to mass transfer limitations in real extraction equipment.

Sample Values:

Feed Flow Rate (L/h): 50 L/h

Feed Concentration (%): 2 wt% solute

Solvent Ratio (mL/mL): 1 mL solvent / 1 mL feed (equal flow rates)

Extract Concentration (%): 8 wt% solute

Relative Efficiency (%): 70%

McCabe-Thiele Method:

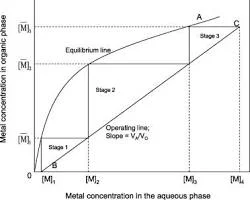

Equilibrium Data: This is crucial for the McCabe-Thiele method. It's typically presented as a graphical plot (called a distribution isotherm) that shows the relationship between the concentration of the solute in the raffinate (extract exiting the process) and the extract (solute leaving with the solvent).

Operating Lines: Based on the feed flow rate, solvent ratio, and material balances, operating lines are constructed on the equilibrium plot. These lines represent the change in concentration of the raffinate and extract as they progress through the extraction stages.

Number of Stages: The number of stages required is determined by the number of steps needed on the McCabe-Thiele diagram for the operating lines to reach the desired extract and raffinate concentrations.

Example Calculation (illustrative, not using all sample values):

Imagine a system where you want to extract a solute from a dilute aqueous feed (water-based solution) using an organic solvent. The feed concentration is 1 wt% solute, and you want to achieve an extract concentration of 9 wt% solute. Let's say the equilibrium data is available as a distribution isotherm.

Plot the distribution isotherm.

Based on the feed flow rate, solvent ratio, and material balances, calculate the slope and a point on the operating line for the raffinate.

Draw the operating line for the raffinate on the isotherm.

Since the desired extract concentration (9 wt%) is higher than the feed concentration (1 wt%), the extract concentration will increase as it progresses through the stages. Draw another operating line for the extract with a specific slope based on the mass balance for the extract.

Starting from the feed composition on the isotherm, step horizontally (representing extraction) until you intersect the raffinate operating line. This represents the raffinate composition after the first stage.

From that point, step vertically (representing movement to the next stage) and then horizontally again (extraction) until you intersect the extract operating line. This represents the extract composition after the first stage.

Repeat steps 5 and 6, moving horizontally and then vertically, until you reach the desired extract concentration (9 wt%) on the extract operating line.

The number of horizontal steps required to reach the desired extract concentration on the diagram represents the minimum number of theoretical stages needed for the extraction process. However, to account for real-world inefficiencies, you'd need to adjust this number by dividing it by the relative efficiency (as a decimal).

Additional Suggestions:

Several software packages can automate McCabe-Thiele calculations and generate the graphical representation.

Pilot plant studies are often conducted to validate the number of stages predicted by the McCabe-Thiele method for a specific extraction system.

By understanding the factors involved and the graphical approach of the McCabe-Thiele method, you can effectively design and optimize liquid-liquid extraction processes.

As previously explained, the McCabe-Thiele method for liquid-liquid extraction doesn't involve a single, definitive equation. It's a graphical technique that utilizes material balances and equilibrium data to determine the minimum number of theoretical stages needed for efficient separation. Here's a breakdown of the relevant factors and how they are used with the McCabe-Thiele method:

Factors:

Feed Flow Rate (L/h): This represents the volumetric flow rate of the feed solution entering the extraction process. (e.g., 100 L/h)

Feed Concentration (%): This indicates the initial concentration of the solute in the feed solution. (e.g., 1 wt% solute)

Solvent Ratio (mL/mL): This is the ratio of the volumetric flow rate of the solvent to the volumetric flow rate of the feed. (e.g., 2 mL solvent / 1 mL feed)

Extract Concentration (%): This represents the desired concentration of the solute in the extract leaving the process. (e.g., 5 wt% solute)

Relative Efficiency (%): This is an empirical factor (often estimated between 50-80%) that accounts for deviations from ideal equilibrium due to mass transfer limitations in real extraction equipment.

Stage Efficiency (%): This term is often interchangeable with relative efficiency and reflects the approach to a single equilibrium stage in a real contactor.

McCabe-Thiele Method:

Equilibrium Data: This is crucial for the McCabe-Thiele method. It's typically presented as a graphical plot (called a distribution isotherm) that shows the relationship between the concentration of the solute in the raffinate (extract exiting the process) and the extract (solute leaving with the solvent).

Operating Lines: Based on the feed flow rate, solvent ratio, and material balances, operating lines are constructed on the equilibrium plot. These lines represent the change in concentration of the raffinate and extract as they progress through the extraction stages.

Number of Stages: The number of stages required is determined by the number of steps needed on the McCabe-Thiele diagram for the operating lines to reach the desired extract and raffinate concentrations.

Example:

Imagine a system where you want to extract a valuable component (solute) from a dilute aqueous feed (water-based solution) using an organic solvent. Let's assume the following:

Feed Flow Rate (L/h): 100 L/h

Feed Concentration (%): 2 wt% solute

Solvent Ratio (mL/mL): 1 mL solvent / 1 mL feed (equal flow rates)

Extract Concentration (%): 8 wt% solute

Relative Efficiency (%): 70% (This will be used later to adjust the number of theoretical stages)

Steps:

Distribution Isotherm: We don't have the actual data, but for explanation purposes, imagine a graph with the x-axis representing the raffinate concentration and the y-axis representing the extract concentration.

Operating Lines:

Raffinate Operating Line: This line is constructed based on the material balance for the raffinate and has a slope of -Solvent Ratio (here, -1).

Extract Operating Line: This line is constructed based on the material balance for the extract and has a slope of Solvent Ratio (here, 1). The exact position of this line depends on the feed concentration.

Number of Stages:

Plot the distribution isotherm.

Draw the operating lines for the raffinate and extract on the same graph. (See image below)

Starting from the feed concentration (2 wt%) on the x-axis, move horizontally (representing extraction) until you intersect the raffinate operating line. This represents the raffinate composition after the first stage.

From that point, move vertically (representing movement to the next stage) and then horizontally again (extraction) until you intersect the extract operating line. This represents the extract composition after the first stage.

Repeat steps 5 and 6, moving horizontally and then vertically, until you reach the desired extract concentration (8 wt%) on the extract operating line.

McCabeThiele diagram for LiquidLiquid Extraction

In this example, it takes 4 steps (horizontal movements) to reach the desired extract concentration on the extract operating line.

Important Note:

The McCabe-Thiele method assumes ideal equilibrium is reached at each stage. In reality, due to mass transfer limitations, this may not be achieved. The relative efficiency (or stage efficiency) is used to account for this by dividing the number of theoretical stages obtained from the McCabe-Thiele diagram by the relative efficiency (as a decimal)

How is it possible to earn money using the knowledge of The Liquid-Liquid Extraction McCabe-Thiele method Calculation?????

The McCabe-Thiele method itself isn't an equation you directly calculate for financial gain. It's a valuable tool used in the design and optimization of liquid-liquid extraction processes. Here's how your knowledge of this method can translate to earning money in real-life applications:

1. Consulting Services:

Chemical Process Design: Offer consulting services to chemical companies involved in processes that utilize liquid-liquid extraction. You can:

Assist in designing new extraction processes by applying the McCabe-Thiele method to determine the optimal number of stages needed for efficient separation.

Help existing plants optimize their extraction processes by analyzing their operating data and suggesting improvements based on McCabe-Thiele analysis.

,h2>Troubleshoot problems in existing extraction units by identifying bottlenecks or inefficiencies using the McCabe-Thiele method.

Environmental Engineering: Many environmental clean-up processes involve liquid-liquid extraction. You can offer your expertise to:

Design extraction systems for removing pollutants from water or wastewater.

Help optimize existing systems for improved efficiency and reduced environmental impact.

2. Research and Development:

Developing New Extraction Processes: Work with research teams in chemical or environmental engineering to develop novel liquid-liquid extraction processes for separating valuable products or removing contaminants. Your knowledge of the McCabe-Thiele method would be crucial in designing and optimizing these processes.

Improving Existing Technologies: Apply your understanding of the McCabe-Thiele method to research ways to improve existing extraction technologies. This could involve:

Developing new extraction solvents that enhance separation efficiency.

Designing innovative contactor designs for improved mass transfer between phases.

3. Educational Roles:

Training Chemical Engineers: Share your expertise by developing training programs or courses for chemical engineers on the application of the McCabe-Thiele method in liquid-liquid extraction processes.

Creating Educational Materials: Develop online resources, tutorials, or textbooks that explain the McCabe-Thiele method and its applications in a clear and concise manner.

Earning Potential:

The earning potential depends on your experience, qualifications, and the specific role you choose. Here are some examples:

Chemical Engineering Consultant: Fees can range from $100 to $500 per hour depending on your expertise and experience.

Research Scientist: Salaries can vary depending on the industry and your qualifications, but typically start around $70,000 annually.

Engineering Instructor: Salaries for engineering instructors at universities can range from $80,000 to $150,000 annually.

Additional Tips:

Software Proficiency: Familiarity with process simulation software that incorporates the McCabe-Thiele method will enhance your value proposition.

Industry Knowledge: Understanding the specific challenges and needs of industries that rely on liquid-liquid extraction will make your services more relevant.

Networking: Building relationships with professionals in the chemical engineering and environmental engineering fields can open doors to new opportunities.

By effectively leveraging your knowledge of the McCabe-Thiele method, you can position yourself for a rewarding career in various sectors that utilize liquid-liquid extraction processes.

Do YOU Want To Earn Money In Various Ways, Click The Link & Explore Your Field of Interest!!!

No comments:

Post a Comment