Definition: Heat exchanger fouling resistance (R_f) is a parameter used to account for the additional resistance to heat transfer caused by the build-up of deposits on the heat exchanger surfaces. This fouling reduces the overall efficiency of the exchanger.

Click the Translate button(see right) on this post to set your Own Language to understand more perfectly!!

Heat Exchanger Fouling Resistance Calculator

Continue Definition:

Heat Exchanger Fouling Resistance (R_f)

Heat exchanger fouling resistance (R_f) is a parameter used to account for the additional resistance to heat transfer caused by the build-up of deposits on the heat exchanger surfaces. This fouling reduces the overall efficiency of the exchanger.

Here's a breakdown of the factors involved:

Overall Heat Transfer Coefficient (U): This is a combined coefficient that represents the overall ease of heat transfer through the entire heat exchanger, including the resistances of the hot and cold fluids, the wall material, and any fouling layers. It's measured in Watts per square meter per degree Celsius (W/(m²·°C)). (Sample value: A clean water-to-water heat exchanger might have a U value of 500 W/(m²·°C)).

Log Mean Temperature Difference (LMTD): This is the driving force for heat transfer in a heat exchanger, considering the inlet and outlet temperatures of both hot and cold fluids. It's calculated using a specific formula and is measured in degrees Celsius (°C).

The Log Mean Temperature Difference (LMTD) formula used for heat exchanger calculations does not directly involve the units of temperature (°C). It's a dimensionless quantity representing the average temperature difference that drives heat transfer across the exchanger.

Here's the formula for LMTD:

LMTD = [(T_h1 - T_c2) - (T_h2 - T_c1)] / ln((T_h1 - T_c2) / (T_h2 - T_c1))

where:

T_h1: Inlet temperature of the hot fluid (°C)

T_c2: Outlet temperature of the cold fluid (°C)

T_h2: Outlet temperature of the hot fluid (°C)

T_c1: Inlet temperature of the cold fluid (°C)

ln: Natural logarithm (present on most scientific calculators)

Important Points:

Even though the formula doesn't explicitly show temperature units, all the temperature values (T_h1, T_c2, T_h2, T_c1) must be in the same consistent unit system (e.g., both in °C or both in Kelvin).

The result (LMTD) will also be a dimensionless value. However, since it represents an average temperature difference, it can be conceptually understood as being in the same unit system as the original temperatures (°C in this case).

Example:

Imagine a heat exchanger with the following temperatures:

T_h1 (hot inlet) = 90 °C

T_c2 (cold outlet) = 70 °C

T_h2 (hot outlet) = 60 °C

T_c1 (cold inlet) = 40 °C

Calculating LMTD:

LMTD = [(90 °C - 70 °C) - (60 °C - 40 °C)] / ln((90 °C - 70 °C) / (60 °C - 40 °C))

LMTD ≈ 27.6 °C (Even though the result is dimensionless, it can be interpreted as an average temperature difference of 27.6 °C)

Heat Transfer Area (A): This is the total surface area available for heat transfer within the heat exchanger. It's measured in square meters (m²). (Sample value: The heat transfer area depends on the specific design of the exchanger. It could be 10 m² for a compact unit or much larger for industrial applications).

Flow Rate (m): This is the mass flow rate of one of the fluids (hot or cold) passing through the heat exchanger. It's measured in kilograms per second (kg/s). (Sample value: The flow rate can vary depending on the application. A typical value might be 2 kg/s for a water flow in a building's heating system).

Specific Heat Capacity (Cp): This is a property of the fluid that indicates how much heat energy is required to raise the temperature of 1 kilogram of the fluid by 1 degree Celsius. It's measured in Joules per kilogram per degree Celsius (J/(kg·°C)). (Sample value: The specific heat capacity of water is around 4.18 J/(kg·°C)).

Relating these factors:

Under clean conditions (without fouling), the heat transfer rate (Q) in a heat exchanger can be calculated using the following equation:

Q = UA * LMTD

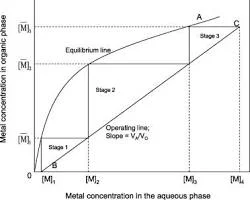

However, when fouling occurs, an additional thermal resistance (R_f) is introduced. To account for this, the equation is modified as follows:

Q =(UA* LMTD) / (1 + R_f)

Isolating R_f:

By rearranging the equation and knowing the values of U, A, LMTD, Q (from the desired heat transfer rate), and the specific heat capacities of the fluids (to calculate the heat transfer based on flow rates and temperature changes), we can solve for R_f:

R_f = (UA / Q * LMTD) - 1

Example:

Imagine a water-to-water heat exchanger with the following parameters:

U = 400 W/(m²·°C)

A = 5 m²

LMTD = 20 °C (calculated based on inlet and outlet temperatures)

Flow rate of hot water (m_hot) = 1.5 kg/s

Flow rate of cold water (m_cold) = 2.5 kg/s

Specific heat capacity of water (Cp_water) = 4.18 J/(kg·°C)

Let's say we want to achieve a heat transfer rate (Q) of 100 kW (100,000 W).

Step 1: Calculate the heat transfer based on flow rates and temperature changes (assuming a desired temperature rise of ΔT_cold for the cold water):

Q = m_cold * Cp_water * ΔT_cold (We can rearrange this equation to solve for ΔT_cold based on the desired heat transfer rate (Q))

Step 2: Substitute all known values into the equation for R_f:

R_f = ((400 W/(m²·°C)) * (5 m²) / (100,000 W) * (20 °C)) - 1

By calculating R_f, you can assess the severity of fouling and its impact on the heat exchanger's performance. It's important to note that this is a simplified example, and real-world calculations might involve more complex factors depending on the specific heat exchanger design and fluids involved.

How is it Possible To Earn Using The Knowledge of the Heat Exchanger Fouling Resistance Calculation In Real Life?????

The knowledge of heat exchanger fouling resistance calculations is valuable for various careers in industries that rely on heat transfer processes. Here's how it can help you earn a living:

Process Engineering:

Heat Exchanger Design and Optimization: Process engineers use fouling resistance calculations to:

Design heat exchangers that are less prone to fouling by considering factors like material selection, flow velocities, and cleaning strategies.

Optimize existing heat exchanger operations by monitoring fouling trends and scheduling cleaning procedures to maintain efficiency.

Maintenance Engineering:

Predictive Maintenance: Understanding fouling resistance calculations helps develop models to predict fouling rates and anticipate maintenance needs. This allows for preventive cleaning and minimizes downtime.

Troubleshooting: By analyzing fouling resistance trends, maintenance engineers can identify the source of fouling (e.g., water quality, corrosion) and implement corrective actions.

Operations Engineering:

Performance Monitoring: Operations engineers use fouling resistance calculations to monitor the ongoing performance of heat exchangers. They can detect efficiency losses due to fouling and take necessary steps to improve heat transfer.

Energy Efficiency Optimization: By maintaining clean heat exchangers, operations engineers can minimize energy consumption for achieving the desired heating or cooling duties.

Beyond Specific Jobs:

Problem-solving: Analyzing fouling data, interpreting results, and recommending solutions for maintaining heat exchanger efficiency require strong problem-solving skills.

Data Analysis: Effectively using fouling resistance calculations often involves analyzing data on flow rates, temperatures, and cleaning frequencies.

Technical Communication: Clearly communicating technical concepts related to fouling and its impact on heat transfer efficiency to colleagues and management is crucial.

Earning Potential:

The salary range for engineers with expertise in heat exchanger fouling analysis can vary depending on experience, location, and the specific industry. However, it can be a valuable skill for securing well-paying jobs in process engineering, maintenance, and operations within various sectors such as:

Chemical Processing

Power Generation

Oil and Gas Refining

Food and Beverage Manufacturing

HVAC Systems

Overall:

The knowledge of heat exchanger fouling resistance calculations equips you with valuable skills for a successful career in industries that rely on efficient heat transfer. It contributes to cost savings through optimized maintenance strategies, improved energy efficiency, and extended equipment lifespan.

Do YOU Want To Earn Money In Various Ways, Click The Link & Explore Your Field of Interest!!!