Definition: Vapor-Liquid Separator (VLS) design is an iterative process that considers several factors to achieve optimal separation. Here we used a very simplified equation to solve the problem. More complicated forms are shown Below.

Click the Translate button(see right) on this post to set your Own Language to understand more perfectly!!

Vapor-Liquid Separator Design Calculator

Continue Definition:

Vapor-Liquid Separator (VLS) design is an iterative process that considers several factors to achieve optimal separation. Here's a breakdown including the equation used and design properties for optimization:

Inputs:

Liquid Flow Rate (LFR) in cu-meter/hr

Gas Flow Rate (GFR) in cu-meter/hr

Liquid Density (ρL) in kg/cu-meter

Gas Density (ρG) in kg/cu-meter

Liquid Viscosity (μL) in cP (centipoise) or Pa*s (Pascal-second)

Gas Viscosity (μG) in cP or Pa*s

Operating Pressure (P) in Pa or bar

Operating Temperature (T) in Kelvin or Celsius

Desired Separation Efficiency (η) - percentage of liquid or gas to be removed

Presence of Solids (if any)

Output Equation (Preliminary Sizing):

One common equation used for preliminary sizing of a horizontal separator is based on Superficial Gas Velocity (VSG):

VSG = GFR / (A * ε)

Where:

VSG - Superficial Gas Velocity (m/s)

GFR - Gas Flow Rate (cu-meter/hr) converted to m3/s (multiply by 1/3600)A = Separator Cross-Sectional Area (m²) =Pi * (D/2)^2 (D = diameter) ε = Void Fraction = Ratio of gas volume to total separator volume (typically 0.5 - 0.7 for separators)

Separator Design Properties for Optimization:

Separator Diameter (D) and Height (H):

Calculated using VSG to ensure droplets aren't carried over by the gas stream.

H/D ratio is also considered for proper liquid residence time.

Inlet Diverter:

Separates large liquid droplets from the gas stream using momentum change.

Design considers inlet pipe size and orientation to avoid excessive pressure drop.

De-entrainment Plates:

Further separate entrained liquid droplets using corrugated plates or mesh. Number of plates depends on separation efficiency requirements.

Mist Eliminators:

Capture very fine liquid droplets using mesh pads or vanes. Selection depends on droplet size and desired efficiency.

Residence Time:

Time liquid spends in the separator for adequate separation. Calculated using separator volume and liquid flow rate.

Pressure Drop:Minimized to reduce operating costs.Achieved by optimizing pipe sizes, internal components, and layout.

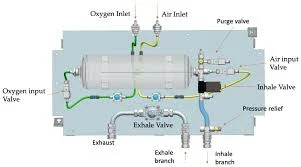

Additional Considerations:

Material Selection: Based on compatibility with process fluids, pressure, and temperature. Level Controls: Maintain liquid level within the separator. Pressure Relief Valves: Protect the separator from overpressure. Safety Features: Consider potential hazards and implement necessary safeguards.

Key Point: The provided equation is a starting point for separator sizing. VLS design software or rigorous calculations are used for final design considering all factors and achieving optimal separation efficiency.

Here's a list of some frequently encountered vapors and liquids along with their densities and viscosities:

Substance, State at Room Temperature, Density (kg/m³), Viscosity (cP at 20°C)

Water (H₂O), Liquid, 1000, 1.002

Ethanol (C₂H₅OH), Liquid, 789, 1.14

Acetone (CH₃COCH₃), Liquid, 784, 0.32

Benzene (C₆H₆), Liquid, 879, 0.801

Air (Mostly N₂), Gas, 1.225, 18.1

Oxygen (O₂), Gas, 1.429, 0.186

Nitrogen (N₂), Gas, 1.250, 0.179

Carbon Dioxide (CO₂), Gas, 1.842, 0.097

The densities and viscosities provided are approximate values and can vary slightly depending on temperature and pressure.

Here are again few gases & liquids name & Density & viscosity for general educational purpose.

Here are 10 more frequently encountered vapors and liquids along with their densities and viscosities:

Substance, State at Room Temperature, Density (kg/m³), Viscosity (cP at 20°C)

Mercury (Hg), Liquid, 13,590, 15.38

Oil (Mineral), Liquid, 900-950 Varies depending on type, (10-200 cP is common)

Sodium Chloride Solution (Brine), Liquid, 1200-1250 Varies depending on concentration, (around 1.5 cP for saturated brine)

Sulfuric Acid (H₂SO₄), Liquid, 1840, 20.0

Ammonia (NH₃), Gas ,0.771, 0.978

Helium (He), Gas, 0.166, 0.034

Hydrogen (H₂),Gas, 0.0899, 0.889

Propane (C₃H₈), Gas, 2.01, 0.22

Ethylene Glycol (HOCH₂CH₂OH), Liquid, 1115, 61.9

Blood, Liquid, 1050, 3.5 - 5.0

The specific equations for vapor-liquid seperator Design:

Designing a Vapor-Liquid Separator involves calculating various parameters to ensure efficient separation of the vapor and liquid phases. The design equations differ based on whether the separator is horizontal or vertical. Below are the general equations and considerations for both types.

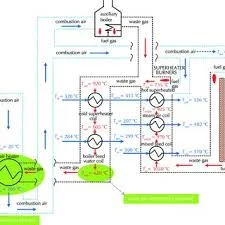

Horizontal Vapor-Liquid Separator

1. Vessel Diameter:

The vessel diameter 𝐷 is primarily determined by the vapor velocity

The vessel diameter D is primarily determined by the vapor velocity 𝑉𝑠 and the gas flow rate 𝑄𝑔

𝐷=(4𝑄𝑔/𝜋𝑉𝑠 x 𝜋𝑉 )**0.5

where 𝑉𝑠 is the vapor superficial velocity and can be calculated using:

𝑉𝑠=[𝐾{(𝜌𝑙−𝜌𝑣)(r-𝜌𝑣)}**0.5]/𝜌𝑣

Here,

K = Capacity factor (typically 0.1 - 0.4 ft/s or 0.03 - 0.12 m/s)

𝜌𝑙 = Liquid density

𝜌𝑣= Vapor density

2. Liquid Volume:

The liquid volume 𝑉𝑙can be calculated from the liquid holdup time 𝑡ℎ and the liquid flow rate 𝑄𝑙

𝑉𝑙=th ×Ql×Q

3. Liquid Level Height: Assuming the liquid occupies a height ℎ𝑙 in the vessel, we can write:

ℎ𝑙=4𝑉𝑙/(𝜋𝐷**2 x𝐿xhl)

where L is the length of the separator.

4. Length of the Separator:

The total length L of the separator includes the length for vapor disengagement L, the liquid collection section, and the inlet and outlet sections.

𝐿=𝐿𝑑+𝐿𝑐+𝐿𝑖𝑛+𝐿𝑜𝑢𝑡+L+L ,

where L=L

Vertical Vapor-Liquid Separator

1. Vessel Diameter:

Similar to the horizontal separator, the diameter D is determined by the vapor velocity V𝑠 :

𝐷=(4𝑄𝑔/𝜋𝑉𝑠 x 𝜋𝑉 )**0.5

2. Liquid Volume:

The liquid volume V is calculated based on the liquid holdup time and the liquid flow rate Q

𝑉𝑙=th ×QL

3. Height of Liquid Section:

The height h of the liquid section is given by:

ℎ𝑙=𝑉𝑙/𝐴

where 𝐴=𝜋𝐷**2 x πD/4

where A= is the cross-sectional area of the vessel.

4. Vessel Height:H of the vessel includes the height of the liquid section, the vapor disengagement height

The total height H of the vessel includes the height of the liquid section, the vapor disengagement height H, and a certain height for inlet and outlet sections:

𝐻=ℎ𝑙+𝐻𝑑+𝐻𝑖𝑛+𝐻𝑜𝑢𝑡 +M + M ,

H=h+M+M

Additional Considerations:

Vapor Disengagement Height:

The disengagement height is generally around 20-30% of the vessel diameter for vertical separators and can be 1-2 times the diameter for horizontal separators.

Retention Time:

For vertical separators, a typical liquid holdup time 𝑡ℎ

For vertical separators, a typical liquid holdup time th is 2-5 minutes.

For horizontal separators, the liquid holdup time can vary based on the application but is typically around 2-10 minutes.

Nozzle Sizes:

The size of inlet and outlet nozzles should be designed based on the flow rates to ensure smooth entry and exit of the phases without causing turbulence.

Mist Eliminators:

In both designs, mist eliminators (such as vane packs or mesh pads) may be included to improve separation efficiency by capturing small liquid droplets carried by the vapor phase.

Summary:

By applying these equations and considering the specific parameters of your application, you can design an efficient vapor-liquid separator.

Do YOU Want To Earn Money In Various Ways, Click The Link & Explore Your Field of Interest!!!

:</b> This is the volume of fluid that needs to pass through the valve per unit time. It's typically measured in gallons per minute (GPM) for liquids or cubic feet per minute (CFM) for gases.</blockquote>

<blockquote><b>Pressure Drop (ΔP):</b> This is the difference in pressure between the upstream and downstream sides of the valve. It's crucial to consider the allowable pressure drop within the system.</blockquote>

<blockquote> <b>Fluid Properties:</b> The type of fluid (liquid, gas, etc.) and its properties like density and viscosity affect how the fluid flows through the valve.</blockquote>

<blockquote><b>Valve Type: </b>Different valve designs (globe, butterfly, ball, etc.) have varying flow characteristics that impact sizing.</blockquote>

<blockquote><b>Required Equation:</b></blockquote>

<blockquote>The most common equation used for valve sizing involves the Flow Coefficient (Cv). The Cv rating represents the amount of water (in US gallons) that can flow through a fully open valve per minute with a pressure drop of 1 psi (pound per square inch).</blockquote>

<blockquote><b>Here's the basic formula:</b></blockquote>

<blockquote><b>Cv = Q / √ΔP / ρ</b></blockquote>

<blockquote>Where:</blockquote>

<blockquote><b>Cv = Flow Coefficient</b></blockquote> , <blockquote> <b>Q = Flow Rate (GPM)</b></blockquote>, <blockquote>ΔP = Pressure Drop (psi)</blockquote> ,<blockquote><b>ρ = Fluid Density (lb/ft^3)</b></blockquote>

<blockquote>Example:</blockquote>

<blockquote>Let's say you need to size a valve for a water line carrying 20 GPM at a pressure drop of 5 psi. The fluid density of water is approximately 62.4 lb/ft^3.</blockquote>

<blockquote>Calculate Cv:</blockquote>

<blockquote>Cv = 20 GPM / √5 psi / 62.4 lb/ft^3 ≈ 5.6</blockquote>

<blockquote>Select Valve Size:</blockquote>

<blockquote>Based on the calculated Cv, you'll consult manufacturer data sheets for valves with a Cv rating greater than or equal to 5.6. This ensures the valve can handle the required flow rate without excessive pressure loss.</blockquote>

<blockquote>Special Note: This is a simplified example. Actual valve sizing often involves additional factors like cavitation, noise control, and future expansion needs. It's recommended to consult with valve sizing software or an engineer for complex applications.

</blockquote>

<div class=)